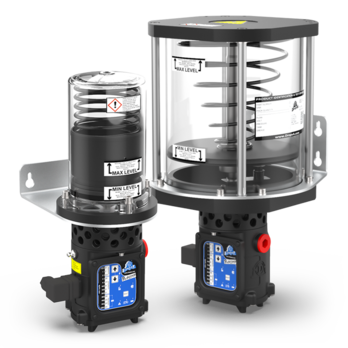

Pneumatic Grease Pumps

A pneumatic system relies on air to power grease or oil to various areas of your application. The size and features of the system can vary dramatically depending on your type of pump and machinery, but they typically include the following components:

- Grease pump cylinder and piston

- Controller

- Pneumatic lines

- Grease or oil applicators